Polypropylene, or PP for short, is like the chameleon of the polymer material kingdom. It can adapt to various roles and applications due to the impressive properties of PP material. Whether you’re a pro-buyer in the polymer industry or just a curious mind eager to know more about types of PP polymers, we’ve got you covered.

As a leading polymer distribution company, we have put together the perfect blend of information and easy-to-digest insights, including a guide to buy polymer online seamlessly without making a guilty decision. So, without further ado, let’s delve into the PP polymer material in depth.

What is PP Polymer Material (Polypropylene)?

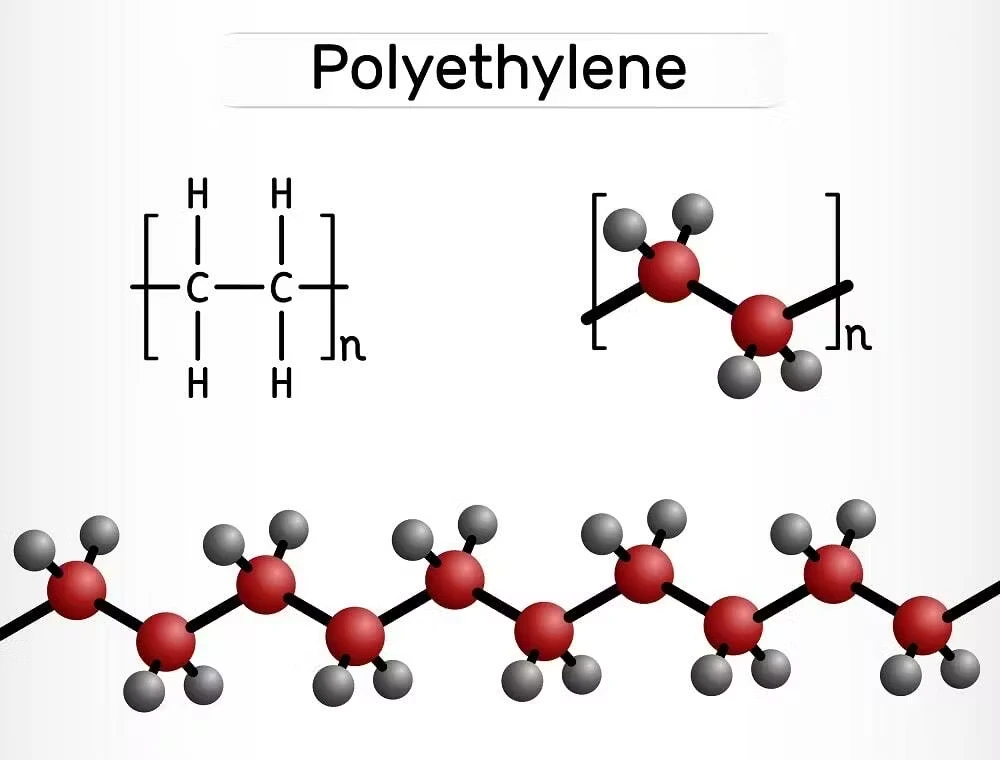

Polypropylene, also referred to as PP is a material that combines the adaptability of a chameleon with the power of a superhero. This thermoplastic polymer is derived from propylene monomers, and it’s a cornerstone in various industries. Polypropylene (PP) belongs to the polyolefin family which is slightly harder than polyethylene. The chemical formula of the plastic is (C3H6)n. It is a commodity plastic with low density and high heat resistance.

Additionally, PP polymer materials have the advantage of being cost-effective, easily moldable, and widely accessible to buy polymers online via the PolyMart Buyer App. PolyMart App is a one-stop source to connect with certified polymer suppliers in India and make well-informed choices.

What are the Properties of PP Polymers?

PP polymer material has been widely seen in our daily lives, but learning about the following properties of PP is crucial for fully understanding them.

PP Polymer Material is Chemical Resistance:

PP polymer material exhibits exceptional resistance to a wide spectrum of chemicals, rendering it suitable for applications in corrosive environments. This property contributes to its extensive use in chemical processing industries.

PP Polymer Material Has High Melting Point:

With a melting point ranging from 130 to 171°C, PP polymer material showcases resilience in the face of elevated temperatures. This characteristic makes it an apt choice for applications involving heat, such as in the automotive and packaging sectors.

PP Polymer Material Yet Has Low Density:

PP’s low density imparts a lightweight quality, proving advantageous in applications where weight is a critical consideration. This makes it an ideal material for items like lightweight packaging and components.

PP Polymer Material Features High Tensile Strength:

Despite its low density, PP also known as Polypropylene polymer material offers commendable tensile strength, ensuring durability in various applications. This strength is particularly valuable in industries where structural integrity is paramount.

PP Polymer Material Provides Good Insulation Properties:

PP exhibits good electrical insulation properties, enhancing its suitability for applications involving electrical components. This property finds application in the manufacturing of electrical appliances and components.

What are the Types of PP Polymers?

Polypropylene polymers come in different types, all tailored to specific requirements. Here is a list of the various types of polymers.

Homopolymer PP Polymer Material:

Characterized by a high melting point, homopolymer PP finds use in applications demanding heightened stiffness and strength. It is commonly employed in industries where structural integrity is critical.

Random Copolymer PP Polymer Material:

This type strikes a balance between flexibility and transparency. Random copolymer PP is often utilized in packaging applications, where clarity and pliability are essential.

Block Copolymer PP Polymer Material:

By combining the attributes of homopolymer and random copolymer PP, block copolymer PP offers a harmonious blend of impact resistance and stiffness. This versatility makes it suitable for a range of applications, including automotive components.

What are the Main Uses of PP Polymers?

Polypropylene uses range from plastic packaging, plastic parts for machinery and equipment, and even fibers and textiles. It is a rigid, semi-crystalline thermoplastic that was first polymerized in 1951 and is used widely today in a range of domestic and industrial applications. The following are the applications of PP polymers.

– Packaging materials

– PP fibers & fabrics

– Medical applications

– Consumer products

– Automotive industry

– Houseware

Last Que: Where to Buy PP Polymers Online?

When striving to buy polymers online, it’s very important to find the right polymer distribution company. PolyMart, an Indian polymer distribution company, operates as a middleman for top-tier solutions when it comes to buying and selling polymers online. Platforms such as PolyMart are more than simply online markets; they are also gateways to a myriad of PP options. These platforms provide simplicity and a wide range of options, allowing you to discover and buy polymers online while staying up to date on the latest polymer trends.